11/17/2021 Mind the Heel Gap

Londoners and Dynafit binding owners tend to be very mindful of gaps. The city-folk are reminded to look out for the gap between train and platform when stepping onto the tube (British for subway). The ski-folk needs to keep an eye on the gap between the back of their ski boots and the heel towers of tech bindings. These are important since forgetting either can lead to falling on one’s face. In this article, we will focus more on ski binding heel gap than the type that can be found underground.

Londoners and Dynafit binding owners tend to be very mindful of gaps. The city-folk are reminded to look out for the gap between train and platform when stepping onto the tube (British for subway). The ski-folk needs to keep an eye on the gap between the back of their ski boots and the heel towers of tech bindings. These are important since forgetting either can lead to falling on one’s face. In this article, we will focus more on ski binding heel gap than the type that can be found underground.

Tech binding heel gaps have been present since the original pin-style bindings were designed by Fritz Barthel in the early 1980s. Unlike most alpine bindings, the toe and heel units on current models of lightweight backcountry bindings do not slide forward or backward when under pressure. That means another mechanism is required to allow skis to flex naturally. This problem was solved with metal heel pins that are designed to slide in and out of tech fittings on a ski boot. By placing a gap between the heel tower and ski boot, tolerance was added for skis to flex as the pins can dive deeper into the boot.

The question is, how much gap should there be between the boot and heel unit? Or asked another way, how much should the metal pins slide into your boot? If there is too small of a gap, the metal pins become fully inserted into the boot and the heel tower itself collides with the boot. This can prevent the release mechanism of the binding from working properly. If the heel gap is too large, your release values might end up on the low side causing pre-release and the aforementioned face plant. In extreme cases when the ski is flexed in reverse, say when picking up your foot lodged in deep snow, the pins can pull out from your boot completely. Therefore, it’s crucial for optimum performance of tech bindings to have the gap configured correctly.

The first step in ensuring you have the right heel gap is knowing the manufacturer's specifications. Luckily, the gaps have become fairly standardized and there are only a few sizes from which to choose. Here are the details:

| ATK Heel Gaps | |

| Candy / Crest / Kulaur | 4mm |

| Haute Route / Plus | 4mm |

| C-Raider / RT | 4mm |

| Raider / Freeraider | 4mm |

| Raider Evo | 4mm |

| Freeraider Evo (2024+) | 3mm |

| Freeraider Evo (2023) | 4mm |

| Revolution / Trofeo / SL | 4mm |

| Atomic Binding Heel Gaps | |

| Backland Summit | 4mm |

| Backland Tour | 4mm |

| Black Diamond Heel Gaps | |

| Helio (all) | 4mm |

| Dynafit Binding Heel Gaps | |

| DNA / Mezzalama | 4mm |

| Low Tech Race 1 & 2 | 4mm |

| RC1 | 4mm |

| Expedition | 4mm |

| Superlite 150 | 5.5mm |

| Superlite 1 & 2 / 175 | 5.5mm |

| Blacklight (2024-) | 5.5mm |

| Blacklight (2025+) / Pro | 2mm |

| Speed / SpeedFit | 5.5mm |

| Seven Summits | 5.5mm |

| Speed Turn 1 & 2 | 5.5mm |

| Speed Radical | 5.5mm |

| Ridge | 2mm* |

| Radical ST / FT | 5.5mm |

| Radical 2.0 | 0.1mm |

| Rotation 10 / 12 / 14 | 0.1mm |

| Rotation 7 / Lite | 5.5mm |

| Vertical ST / FT | 5.5mm |

| Fritschi Heel Gaps | |

| Vipec / Evo | 1mm |

| Xenic | 1mm |

| Fischer Heel Gaps | |

| Tour Race 1, 2 & 3 | 4mm |

| G3 Heel Gaps | |

| ION (all) | 0mm |

| ZED 9 / 12 | 0mm |

| Grizzly Heel Gaps | |

| GR 98 | 4mm |

| Olympic | 4mm |

| Marker Heel Gaps | |

| Alpinist | 0mm |

| Plum Binding Heel Gaps | |

| Race (all) / S170 | 4mm |

| Oazo / Pika / WEPA | 4mm |

| Serak / Kairn | 4mm |

| Guide / Yak | 4mm |

| Summit | 4mm |

| Salomon Binding Heel Gaps | |

| MTN | 4mm |

| MTN Summit | 4mm |

| Ski Trab Binding Heel Gaps | |

| TR-Race / Adjustable | 4mm |

| Gara Titan | 4mm |

| Titan Vario (LT) / Release | 5mm |

| Titan Vario.2 | 0.75mm |

| Hagan Binding Heel Gaps | |

| Core / Core Pro | 4mm |

| Ride / Pure | 4mm |

| Ultra / ZR | 4mm |

| La Sportiva Binding Heel Gaps | |

| RSR / RST | 4mm |

| Kreuzspitze Binding Heel Gaps | |

| EL | 6mm |

| RS / RS-A | 6mm |

| SCTT / SCTTT | 6mm |

| GT / GT 2.0 | 6mm |

| Slatnar Binding Heel Gaps | |

| ST Touring | 1mm |

* Early production of the Ridge binding was 0.1mm.

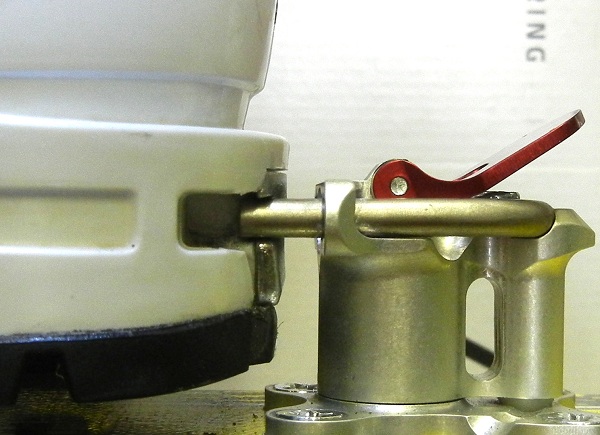

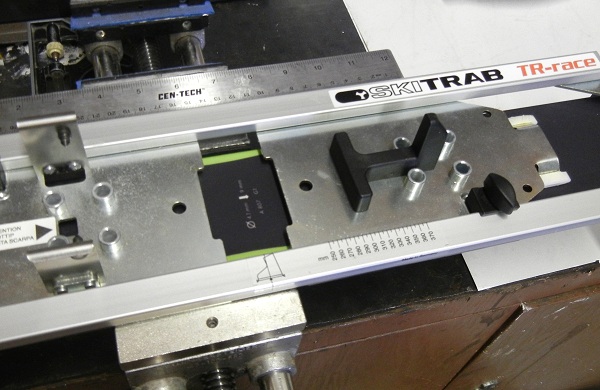

So how do you set the heel gap correctly? That mostly depends on whether your heel piece has a fore/aft adjustment mechanism. If the heel does not adjust, you have a race binding and it needs to be mounted precisely for your boot. Binding manufacturers provide their dealers with jigs designed to make setting this gap a snap, though with manufacturing tolerances you can't blindly trust them. We specialize in fixed race mounts at Skimo Co and have custom tools and processes to ensure accuracy. This means that, uniquely, we can guarantee a precise race mount.

Adjustable bindings, on the other hand, let you work with various boot sole lengths. Ranges of 20mm to 40mm of adjustment are typical. With Dynafit touring bindings, a few twists with a Pozidriv screwdriver will set your gap, though a flathead will do in a pinch. For Trab adjustable bindings, a socket wrench may be needed. Plum includes a mini Torx key with their adjustable bindings. Whichever the tool, you will have some flexibility when it comes to changing boots and a margin for error when mounting by hand.

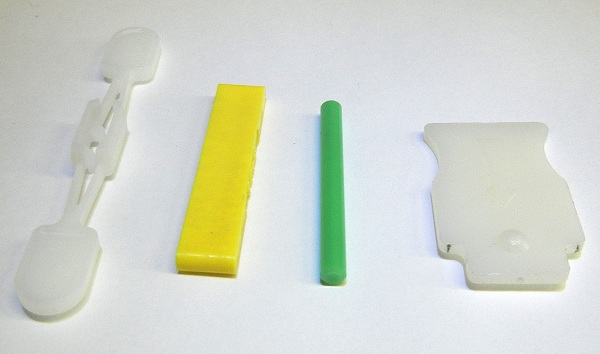

To help measure the heel gap, some manufacturers include various shims that approximate their specified heel gaps. These should slide snugly between the boot and the heel housing. For adjustable bindings, you can tune the fore/aft settings with the shim in place until it fits. See below for a sampling of the shims that might ship with your bindings.

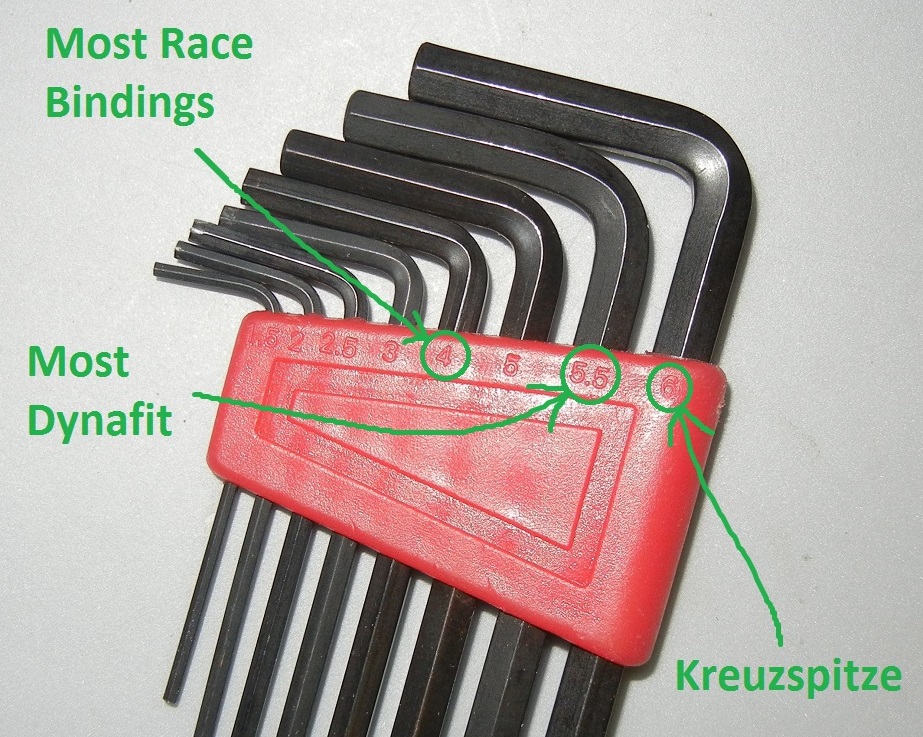

If you do not have a shim, various arrangements of pocket change will do the trick. Two unworn nickels measure just under 4mm, and adding a quarter will approximate the 5.5mm gap. Alternatively, a cheap set of metric hex keys makes a great heel spacer kit.

In conclusion, it is important to be mindful of your tech binding heel gap, sometimes referred to as the “tech gap”. You should only need to set it once per boot configuration, but please make sure it is as close to manufacturer spec as you can get it. If you would like more frequent reminders of gap dangers, we recommend a sightseeing tour of the London underground.

This article was originally published on 12/26/2013 and was last updated on 11/17/2021.

Comments

Here's my question: Do I measure a 4mm space when the gauge (like a 4mm hex wrench) is inside that channel? Or is the 4mm gap supposed to be measured from the boot heel to the parts of the heel piece on either side of the channel, since they are closer to the boot? Thanks.

Quick question. I’ve got a pair of what I believe are "Dynafit TLT Speed" bindings from around 2011 that are on their last legs. They are gray and have a 5-hole pattern. The heel gap is set at 5 mm right now, but I’m not sure if it should actually be 4 mm or 5.5 mm.

They are these.

Compared to a pair of Speed Rads I have around, the pins look shorter and the heel nub is bigger, so I’m a bit confused. Any insight would be great. Thank you!

I just bought a pair of used demo dynafit ski with a radical st binding. The tech set the gap at 5mm but i am getting a heel release of 121nm and 134nm instead of the recommended 229nm.

Could the demo style binding (on slide plate) change the gap setting?

Is it ok to close up the gap until i get the 229nm release or is that a bad idea?

The gap should remain the same, but you can adjust the release value screws in order to dial in the release, as the RV numbers on the heel housing may not be perfectly calibrated.