12/29/2020 Closing The Tech-Binding Achievement Gap

By Tim Chappell, Lead Tech at Skimo Co

As binding technology evolves and new gear hits the shelves each fall, we at Skimo Co get excited about exploring all the new features and designs in the pipeline - just ask the reps who get battered with our nerdy technical questions! Of those innovations, the progression of the gapless heel piece (aka kiss-gap or zero-gap) has been one of the most significant. A notoriously mysterious feature, the gapless binding is catching on as many brands now offer at least one binding using this design concept.

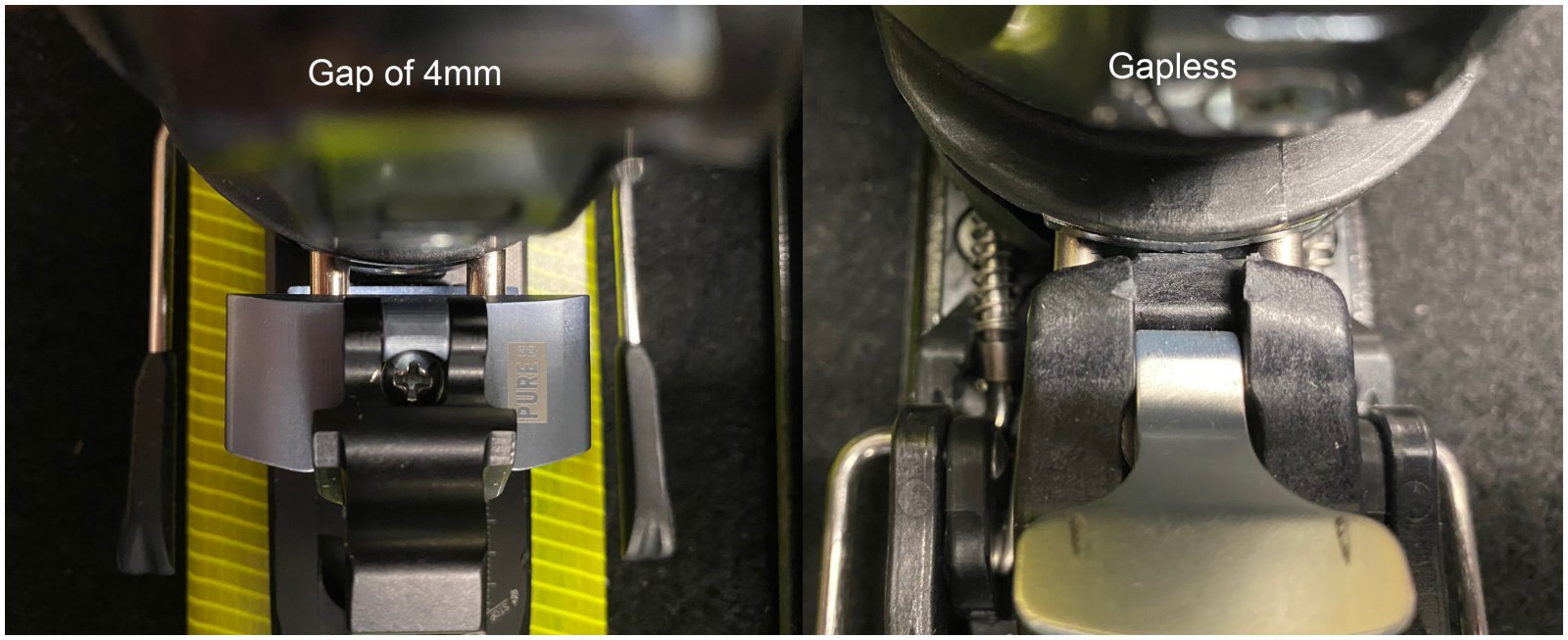

As an overview for those unfamiliar, the gapless system features springs along the base plate that allows the heel tower to float forward and backward with the boot as the ski flexes. This results in a smoother ride with a more consistent release. To truly understand its benefits though, it helps to take a deeper dive. Let’s start with traditional tech bindings and their idiosyncracies.

In their ideal form, traditional tech bindings are simple, low-weight, and durable which has understandably led to skintrack ubiquity. There are, however, two main quirks. The first is that the release mechanism may not be as consistent when compared to a DIN-certified alpine binding. This stems from the fact that the size of the gap between boot and heel tower is correlated to the force needed to release out of the system. During a turn or dip, the boot slides back on the pins and closes the gap. Afterwards, as the ski re-cambers between turns, the gap then increases. As the size of the gap expands and contracts while skiing, the force needed to release out of the binding can fluctuate. If the gap closes completely, for example in a hard landing, it's possible the release is altogether disabled. Secondly, the overall feel of these bindings tend to be less poppy than alpine bindings and possibly less smooth in firm conditions - it's up to the ski what you feel.

The impetus leading to gapless bindings was the desire to join the simple technology of a touring binding with the smooth, shock-absorption performance and consistency of an alpine heel piece. Engineers achieved this marriage by mounting the heel piece on an adjustable track with a calibrated spring. No gap between the boot heel insert and binding housing adds that spring's resistance to the flex of the ski. The boot heel insert does not move nearly as much on the binding pins which results in a more consistent release value, throughout the flex of the ski. An added benefit is that the spring in the track adds rebound to your ski, providing energy as you come out of a turn. One disadvantage to this design, however, is that the absorption makes for slightly less efficient skinning since reweighting the ski causes the heel to move back a touch. All-in-all, the gapless binding provides a smoother ride with a more consistent release.

However, today’s offering of gapless bindings didn’t just happen overnight. Its design journey is one of heavy-awesomeness tweaked to a lightweight engineering feat. Early forays into the realm of gapless bindings were introduced in full-featured tech bindings such as the G3 ION and the Radical 2 from Dynafit. These bindings were (and still are) a fantastic option for skiers looking for the performance and feel offered by alpine bindings while providing the ability to tour efficiently. When these bindings first hit the shelves, many skiers were quick to get on the bandwagon. Not just experienced tourers looking for added performance, but also newcomers excited about the versatility that these bindings offered. Skiers who wanted to get a bit further out of the gates or test the waters in the backcountry finally had a binding option that could hold its own on any type of tour, in any terrain.

Although the bindings were proven to work, a problem remained. It quickly became evident to many early adopters that there always seemed to be someone else going faster, farther, and with less effort. “How is that possible? I have the newest gear, the floatiest skis, the most Instagram likes, and I skin 4,000 feet a day on a diet of only avocado and muesli!”

The 600-gram elephant in the room for skiers on gapless bindings was the realization that in order to go further out there in less time, they had to go lighter. These gapless bindings weighed around 600 grams per ski. While significantly lighter than the 1000g frame bindings they surpassed, 600 grams was still a heavyweight in the touring binding world, where other options dipped below the 150 gram range.

Skimo Co employee Calum proves that gapless bindings make for cushy corn cruisin'.

For years gapless bindings were only offered as fully featured without an option to pick and choose features. The reality is that going lighter requires sacrificing some features and only keeping the essentials. In essence, if the binding choices were like shoes, there were only flip-flops or logging boots available. Where were the running shoes?

With this in mind, skiers began contemplating the worthiness of each binding feature.

“Do I need a brake? No, and if I drop it, I’ll save 150 grams. What about an adjustable release? No again, and this time I’ll shave 100 grams. Do I need an adjustment plate? Nope. There goes 80 grams. Do I need multiple risers? Bye bye 80 grams. Do I need a shock absorbing gap-less heel? Hmm, debatable. I’d be happy to take the 100 gram weight penalty if only I could keep just that and lose all the other junk…”

In recent years, binding manufacturers have put their engineering teams to task, developing technologies in an effort to close the metaphorical gap between full featured and ultralight touring bindings. And, oh man, did they get this one right! There are now gapless options in the sub-300 gram range, with more surely to come. Bindings such as the Fritschi Xenic, Marker Alpinist, and the Skimo Co staff favorite, the Ski Trab Vario 2.0, are all fantastic bindings that bail on unnecessary features. These bad boys offer outstanding performance while keeping the weight down like Richard Simmons during a high-intensity infomercial. What is not to love about a sub-300 gram binding with consistent, reliable release and a plush, suspension-like feel? You even have the option to add brakes back on (if you want something to slow you down..)

Gapless bindings are becoming more prevalent on the shelves and have added to the ever-growing list of available binding options. But what does that boil down to when it comes to finding the right binding for you? Start with determining what you are intending to do with the ski you are mounting them on and then what weight range you would like to be in. Finally, you’ll need to differentiate the features that you need from the ones you want, and, of course, the features you are okay losing. These considerations will point you in the right direction.

Having a gapless feature is quickly becoming a requirement for customers and manufacturers are working hard to ensure that they provide this as an option across the board from the ultra-light to the beefy. We are getting close to having a binding for just about skier and when that happens, we all win. The dedicated “it’s all about the downhill” skier can drop half the weight and maintain the performance they require and the “I need to go fast and light” skier can add additional performance and consistency for just a few extra grams.

Clearly this demand is spurring new innovations and we can’t wait to see what next season brings. Sub 300 gram gapless bindings has set a new benchmark that will only get better from here. Who knows, maybe someday soon we’ll see gapless race bindings or even fully-featured bindings in the 200-gram ballpark!

Comments

That demographic is almost as cray cray about weight as this one.

There is such a thing as "light enough", beyond which no one -- other than a scale toting nerd -- can tell the difference.

Make the bindings better -- less fiddly, less likely to ice up, with a wider range of adjustability -- by all means. But FFS let it go about the weights.

1/19/2021

Uptrack Etiquette